Treating Corroded and Damaged Flanges

1. THE PROBLEM

FLANGE FACE CORROSION

Pipeline corrosion is a widespread issue in a number of sectors in particular the oil and gas industries. The remedial action required can often require multiple solutions and service providers, increasing costs and scope duration.

KLINGER understands that oil and gas companies are under constant pressure within the current economic environment, and we're here to offer cost-effective solutions to reduce downtime and maximize efficiency.

2. THE SOLUTIONs

REACTIVE GASKET SOLUTIONS

KLINGER SAFEGUARD GASKET

The Safeguard has been developed by KLINGER as a solution to sealing corroded flanges which are particularly evident in the offshore environment.

Simple to install, the Safeguard limits further corrosion and provides a safe and efficient sealing solution, and enables users to plan for necessary flange face repair.

Benefits:

- Fire safe to API 6FB

- Continuous service up to 260°C

- Suitable for RTJ, RF, mismatched RTJ to RF, and dissimilar metallurgy flange connections

- Suitable for sizes 1/2"-24" and pressure classes 150-2500

- Fire Safe primary seal combined with biaxially orientated, structurally modified PTFE that conforms to pitting.*

*other metallurgies available, contact KLINGER for acceptance criteria

REACTIVE Machining SOLUTIONS

KLINGER understands machining of a flange face is always the first choice remedial action, where it is permissible to machine the flange face. KLINGER integrity services' dedicated machining team can solve all on-site problems.

With extensive experience, a proven industry record, and the most advanced equipment, we provide a fast, comprehensive, and safe service.

oN-SITE MACHINING SERVICES

Our Capabilities Include:

- Weld repair

- RTJ machining

- Hub re-machining

- Full exchanger machining service

3. THE FUTURE

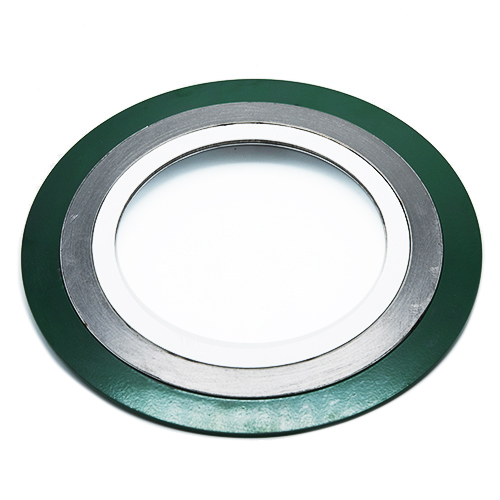

klinger maxiflex pro x gasket

The Maxiflex Pro X has been designed to offer a standard spiral wound-style gasket that has been specifically engineered to prevent the ingress of potentially corrosive media into the flange sealing area.

By combining Mica and Graphite in the sealing element we provide a safe, tight, and long-term solution to Hydrocarbon based industries and those exposed to saltwater.

The proactive element of the Pro X is engineered through the inclusion of a KammProfile based inner ring, faced with biaxially orientated, multi-directional PTFE.

Features & Benefits:

- Fire safe to API 6FB

- Designed to ASME B16.20 2017

- Gasket factors; M: 3 Y: 10,000

- Standard Construction: 316SS winding strip / MGM filler / 316L KAMM INNER / PTFE Facing

*Alternative metallurgies can be specified. Discuss with our technical team.

Find out how our experts can help you today!