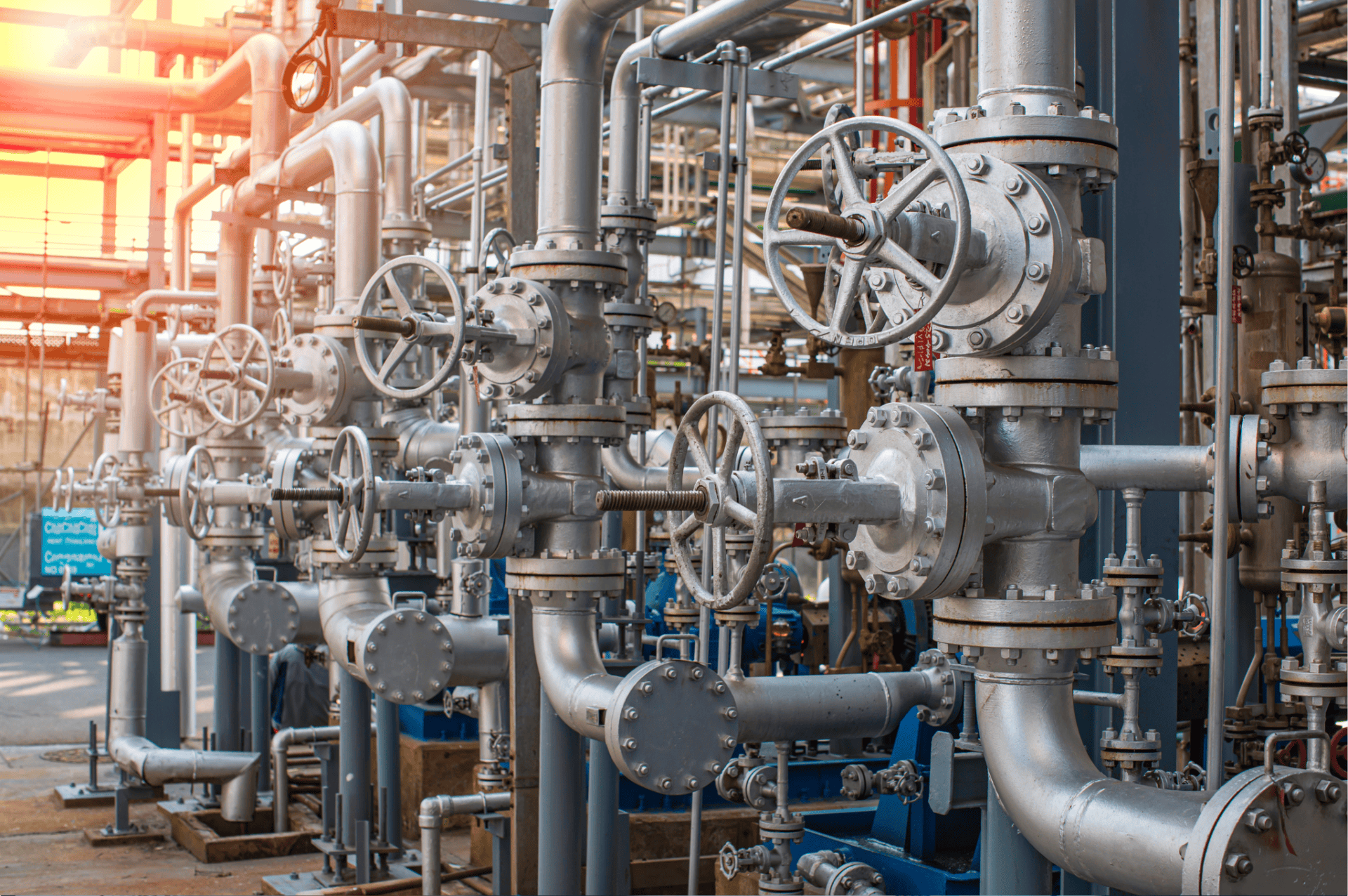

Ring Type Joints (RTJs)

RTJs are designed to be used in high pressure applications and can be manufactured from a number of materials to suit the process media and the flange materials. RTJs are precision machined metallic rings which are designed to be used with API 6B, ASME B16.5 and API 6BX (dependent on the gasket style) flanges. RTJs…

RTJs are designed to be used in high pressure applications and can be manufactured from a number of materials to suit the process media and the flange materials.

RTJs are precision machined metallic rings which are designed to be used with API 6B, ASME B16.5 and API 6BX (dependent on the gasket style) flanges. RTJs are often used in offshore applications and certain styles can be adapted for subsea installation.

KLINGER hold a large range of RTJs in stock in a number of profiles and materials.

Properties of RTJs

- Can be used for high pressures.

- Wide range of materials available.

Downloads

Save our detailed product information for later use

Related industries

Chemical

Sealing technology from KLINGER meets the high requirements of the chemical and petrochemical industry. We focus on ensuring plant and environmental safety by providing top-quality and durable products.

Oil & Gas

Our products provide the leading solutions both on and offshore within the oil & gas industry. We provide the first choice in terms of safety and reliability.

Energy

The energy sector has a high demand for safe and reliable products. KLINGER is able to provide high-quality advanced solutions for this industry.

Marine

Industrial seals and valves provide safe, reliable and efficient operations in the marine industry, especially in LNG. These components help prevent leaks and maintain proper pressure, ensuring safe transportation and storage of LNG, reducing maintenance costs and improving efficiency.