Borosilicate Gauge Glasses

Durable and corrosion-resistant, KLINGER borosilicate gauge glasses offer exceptional clarity and strength for liquid level gauges in demanding conditions up to 400 °C and 340 bar.

KLINGER gauge glasses are suitable for installation in liquid level gauges of almost any type. The Quality of a sight (gauge) glass depends mainly on the chemical composition and mechanical strength of the glass material. Analyses and acid/alkali tests constantly ensure a high glass quality. The mechanical strength is reached by thermal prestressing.

We Offer:

- Transparent gauge glass

- Reflex gauge glass

- Round gauge glass

KLINGER Transparent Gauge Glasses

KLINGER transparent glasses are manufactured from “extra-hard” borosilicate glass. The surfaces on both sides are finely polished to ensure optimal transparency.

Product Advantages

- Excellent mechanical strength

- Maximum smoothness and hardness

- Extremely resistant to boiler water

- Corrosion resistant

- Certified according to most international standards

Applications

Up to 35 bar saturated steam, reflex glasses provide the optimum solution: they are corrosion resistant and provide a perfectly clear indication. Transparent glasses are preferably used with heavily polluted, viscous or acidic media at service conditions up to 340° bar or temperature up to 400 °C.

KLINGER transparent glasses are available in three different Types: A, B, H and TA-28. For the specific overall dimensions and the application range please refer to the product catalogue.

Related industries

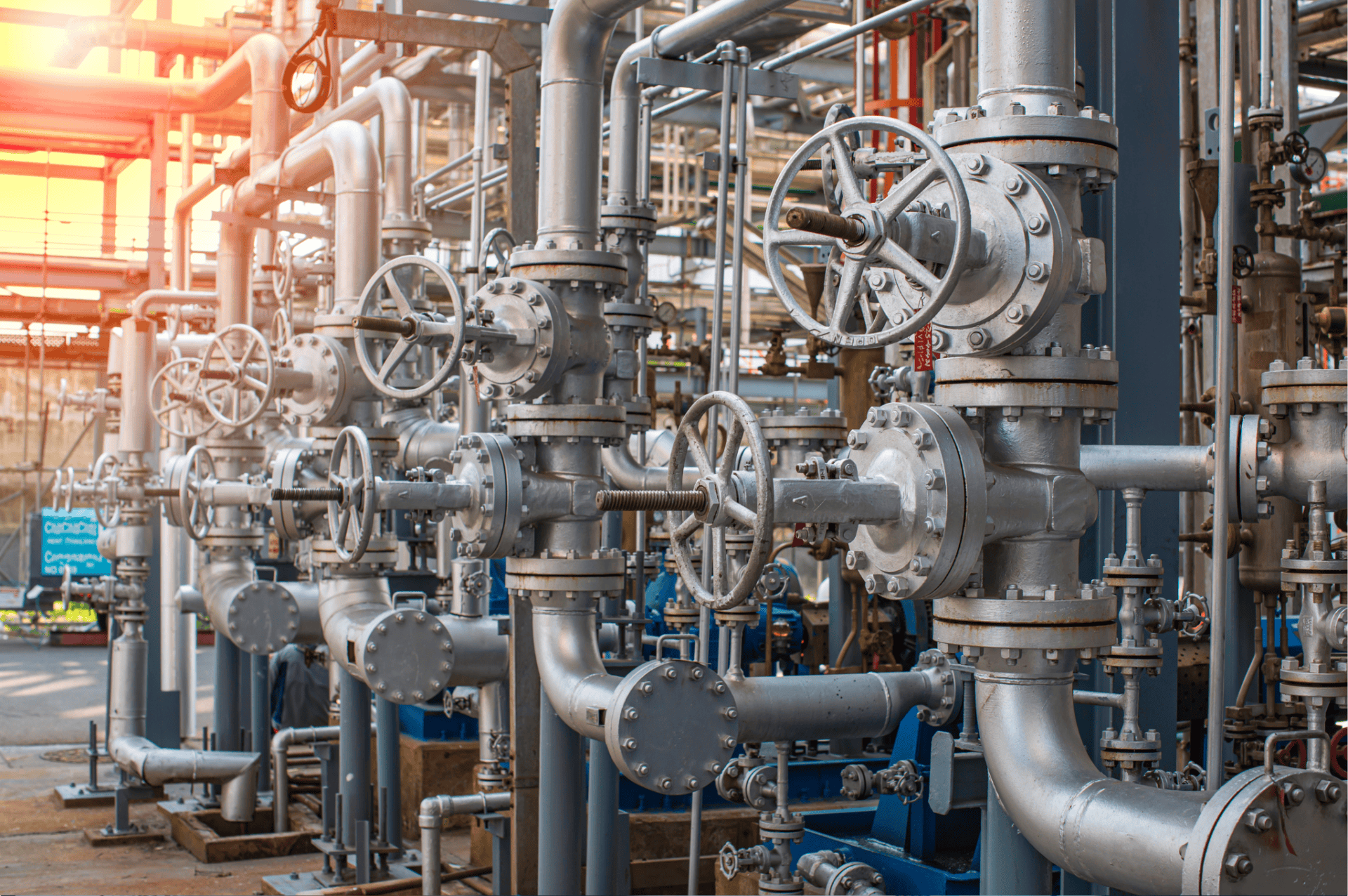

Oil & Gas

Our products provide the leading solutions both on and offshore within the oil & gas industry. We provide the first choice in terms of safety and reliability.

Chemical

Sealing technology from KLINGER meets the high requirements of the chemical and petrochemical industry. We focus on ensuring plant and environmental safety by providing top-quality and durable products.

Pharmaceutical

Cleanliness and hygiene are non-negotiable factors within the pharmaceutical industry. Our products are in full compliance with the sector’s strict and demanding regulations and stand out thanks to their long service life.

Marine

Industrial seals and valves provide safe, reliable and efficient operations in the marine industry, especially in LNG. These components help prevent leaks and maintain proper pressure, ensuring safe transportation and storage of LNG, reducing maintenance costs and improving efficiency.

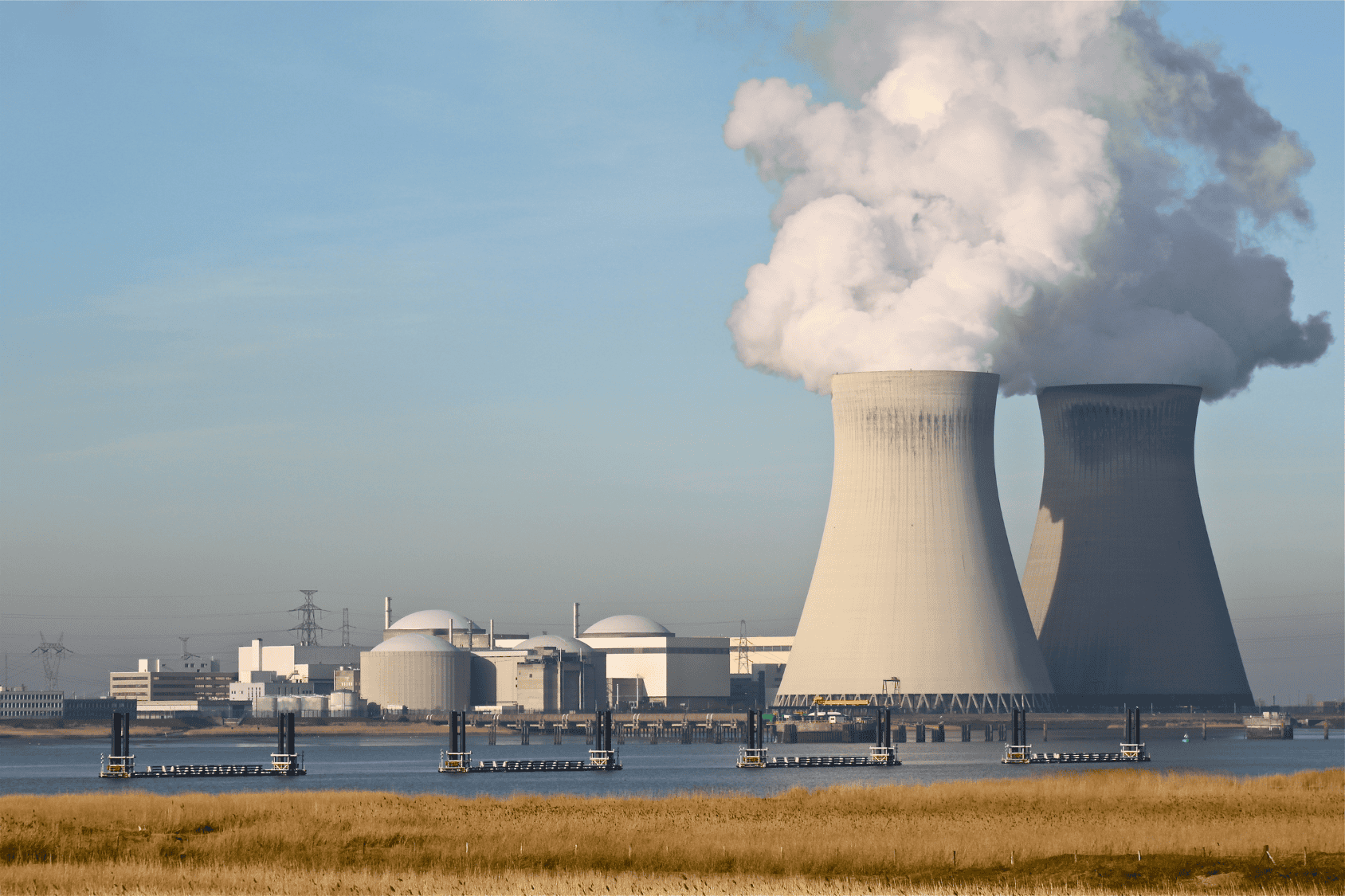

Nuclear

KLINGER supplies the nuclear industry with high-performance gaskets, valves, and seals, ensuring safety, reliability, and regulatory compliance.