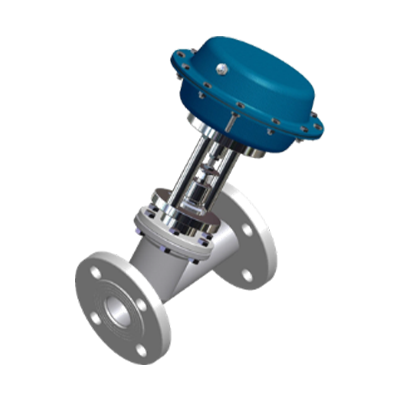

Control Valves – Precision Flow Regulation

Our range of control valves offers precision flow regulation, robust construction, and a wide selection of configurations to suit industrial applications – from general service to heavy-duty, cryogenic, and sanitary processes.

Our range of control valves offers precision flow regulation, robust construction, and a wide selection of configurations to suit industrial applications – from general service to heavy-duty, cryogenic, and sanitary processes.

Product Advantages – Control Valves

- Precise and stable flow regulation

- Low maintenance requirements

- Reliable sealing for tight shut-off and minimal leakage

- Suitable for high-temperature, pressure, and thermal cycling conditions

- Durable internal components for long service life

- No erosion on critical control surfaces

- Servicing possible without full removal from the system

- Fire-safe design

- Compatible with automation and actuation systems

Each valve is tested, calibrated, and delivered ready for operation, ensuring long-term performance with minimal maintenance.

Why Choose Our Control Valves?

- Comprehensive Range – General service, heavy duty, cryogenic, and sanitary solutions

- Customisable – Multiple materials, trims, and actuation options available

- Precision Performance – Equal percentage or linear characteristics for accurate control

- Maintenance-Friendly – Fully tested, calibrated, and designed for long service life

Why Choose Our Control Valves?

KLINGER Integrity Services can provide on-site support, installation, and testing for your control valves – ensuring they are set up correctly and operating at peak performance from day one.

Our team is also on hand to assist you in selecting the right valve for your specific application.

Contact Us today to speak with our experts about selection, installation, or maintenance.

Overview of types Control Valves – Precision Flow Regulation

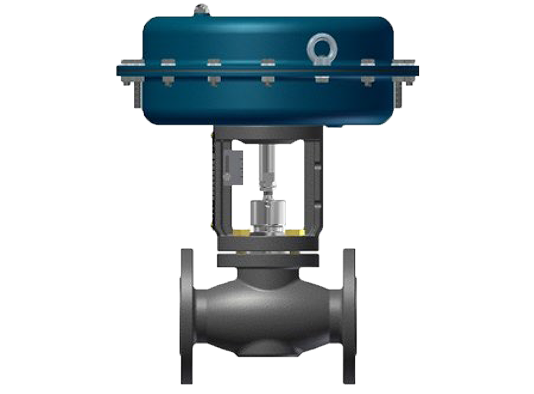

EURO Series – General Service

2-Way Globe Control Valves

- DN 15–150, PN26 or PN40 rating

- Flanged UNI/DIN PN16 or PN40

- Soft (Class VI) or Metallic (Class IV–V) sealing

- Equal Percentage (EQP%) characteristic (linear available)

- Pneumatic diaphragm actuation (max 3 bar)

- Temperature: -20°C to +205°C

- Precision machined plug and seat for excellent control performance

- Best suited for medium/light duty regulation

Options: Linear characteristic, metallic seal, stainless-steel actuator, low-noise trim, stroke limiter, handwheel, positioners, feedback systems, airset, or electric actuators (230V AC, 110/115V AC, 24V AC/DC).

Series 800 – Globe Control Valves

- DN 15–150, PN16/PN40 rating

- Flanged UNI/DIN PN16 or PN40

- Screwed single seat with bottom inspection

- Equal Percentage characteristic

- Pneumatic diaphragm actuation (max 3 bar)

- Temperature: -20°C to +205°C

- Ideal for medium/light plants with easy inspection access

Options: ANSI 150 drilling available, stainless-steel actuators, 3-way (mixing/diverting) option (see Series 803), low noise trim, stroke limiter, handwheel, automation accessories, or electric actuators.

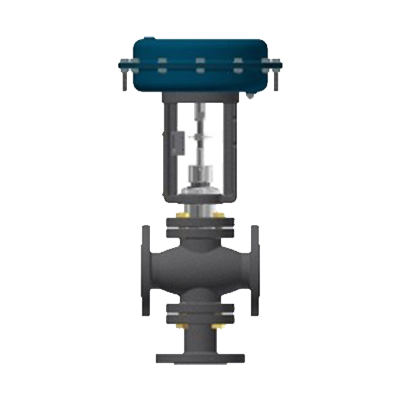

Series 2000 – Heavy Duty Control Valves

- DN 15–200, PN16/PN40, ANSI 300

- Modular globe body construction for easy upgrade

- Equal Percentage characteristic

- Pneumatic diaphragm actuation (max 3.5 bar)

- Temperature: -196°C to +350°C

- Designed for liquid and gaseous services in severe conditions

Options: High-temperature bonnet, cryogenic extension, bellows seal, ANSI drilling, 3-way valves, stainless actuators, stroke limiter, and full automation options.

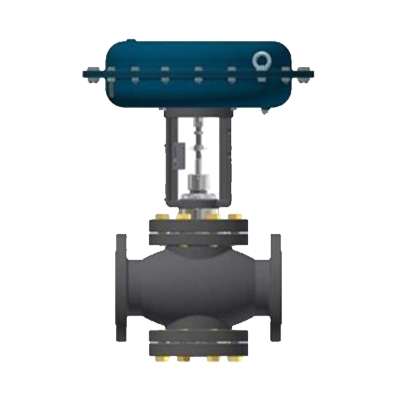

Series 803 – 3-Way Diverting/Mixing

- DN 15–150, PN16/PN40 rating

- 3-way globe body, diverting or mixing function

- Screwed seats with guided plug for stable control

- Pneumatic diaphragm actuation (max 3 bar)

- Temperature: -20°C to +205°C

Options: Metallic seal, ANSI drilling, stainless actuators, handwheel, positioners, and feedback systems.

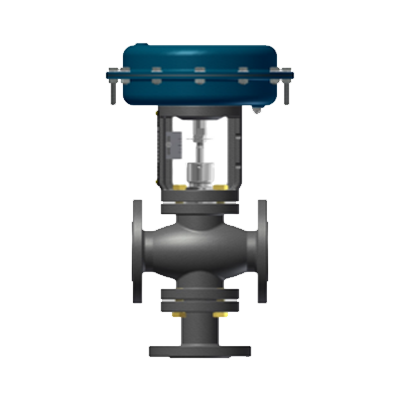

Series 2003 – Heavy Duty 3-Way

- DN 15–150, PN16/PN40, ANSI 300

- Linear characteristic

- Temperature: -196°C to +350°C

- Modular construction, upgradeable for special applications

Options: High-temperature extension, cryogenic extension, bellows seal, ANSI drilling, stainless actuators, and full automation options.

Series 3000 – Low Flow Valves

- DN 10–50 (¼”–2”), PN16–160, ANSI 150–600

- Available in flanged, threaded, BW/SW welded, or clamp connections

- Designed for microflow control in pilot or experimental plants

- Constructed from stainless steel or special alloys (Hastelloy, Duplex, Monel)

- Temperature: -196°C to +350°C

Options: 3-way option (Series 3003), cryogenic extension, high-temperature bonnet, bellows seal, piston actuators (ON/OFF), and full automation packages.

Series 3003 – 3-Way Low Flow

- DN 15–50 (½”–2”), PN16–100, ANSI 150–600

- Diverting or mixing function

- Short delivery time available for special builds

- Cryogenic and high-temperature designs offered

Series 4000 – Cryogenic Control Valves

- DN 10–50, PN16/40

- Welded BW connections for DN10–25

- Designed for vacuum-insulated cryogenic plants

- Temperature: -196°C to +100°C

- Fully removable internal parts for easy maintenance

Options: Stainless actuators, handwheel, stroke limiter, cleaning for oxygen service, and special project design on request.

Series 1000 – Compact 2-Way

- DN 15–100, PN16

- Compact, solid construction with high flow coefficient

- Temperature: -30°C to +200°C

Options: Plug sealing in HPP PEEK, linear characteristic, ANSI 150 drilling, handwheel, and positioners.

Series 600/SQ – Sanitary Control Valves

- DN 15–100, PN10

- Angle design body in 316L stainless steel for pocket-free drainage

- Ideal for food, pharmaceutical, cosmetic, and biotech applications

- Temperature: -15°C to +160°C

Options: 3-way design, steam barriers, stainless actuators, automation accessories, and electric actuators.

Related industries

Marine

Industrial seals and valves provide safe, reliable and efficient operations in the marine industry, especially in LNG. These components help prevent leaks and maintain proper pressure, ensuring safe transportation and storage of LNG, reducing maintenance costs and improving efficiency.

Oil & Gas

Our products provide the leading solutions both on and offshore within the oil & gas industry. We provide the first choice in terms of safety and reliability.

Energy

The energy sector has a high demand for safe and reliable products. KLINGER is able to provide high-quality advanced solutions for this industry.

District Heating

We are proud to assist in providing durable leak-proof materials for all heating needs across the district.