On/Off Valves – Reliable Shut-Off Solutions

Our comprehensive range of ON/OFF valves is designed to provide reliable, maintenance-free shut-off for a wide variety of industrial applications.

Our comprehensive range of ON/OFF valves is designed to provide reliable, maintenance-free shut-off for a wide variety of industrial applications. Built for performance and durability, these valves deliver consistent operation in demanding conditions – from standard liquid and gas service to high-temperature steam and cryogenic applications.

All ON/OFF valves are fully tested, calibrated, and ready for immediate use, ensuring trouble-free installation and long-term service life.

Product Advantages

- Reliable full shut-off with minimal leakage

- Low maintenance and long service life

- Suitable for high-temperature, cryogenic, and steam applications

- Durable sealing surfaces resistant to erosion

- Servicing possible without removal from the pipeline

- Fire-safe design

- Compatible with pneumatic, electric, or manual actuation

- Compact and robust construction for demanding industrial conditions

Why Choose Our ON/OFF Valves?

- Wide Product Range – From compact micro-valves to heavy-duty globe valves

- Reliability – All valves tested, calibrated, and maintenance-free

- Flexibility – Multiple connection types, materials, and sealing options

- Versatility – Suitable for liquids, gases, steam, and extreme temperatures

- Customisation Available – Options for automation, feedback, and emergency operation

Please note that the maximum operating temperature of each KLINGER AB-cock depends on the respective operating pressure as well as on the materials of body or sealing. The pressure and temperature limits are shown in the P-/T-diagrams which can be found in the respective product catalogue.

Overview of types On/Off Valves – Reliable Shut-Off Solutions

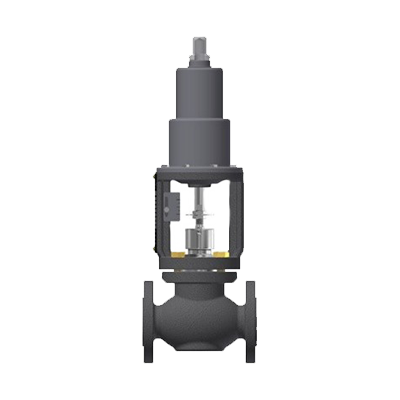

Globe Valves – General Service Series VPFA & VPFA/3

- 2-way and 3-way configurations

- DN 15–65, PN16 pressure rating

- Soft sealing (Class VI) for tight shut-off

- Suitable for liquids, gases (up to 16 bar) and steam (up to 8 bar)

- Compact, reliable solution for general service applications

- Pneumatically actuated (max 8 bar supply)

- Temperature range: -5°C to +180°C

Globe Valves – Enhanced Performance

Series VPOO & VPOO-E

- 2-way and 3-way designs with screwed seats

- DN 15–100 (up to DN 150 for Heavy Duty versions)

- PN16 or PN40 pressure ratings, ANSI 300 option on Heavy Duty

- Available with soft (Class VI) or metallic (Class IV–V) sealing

- Wide temperature range: -20°C to +205°C (Heavy Duty: -196°C to +350°C)

-

Options include:

- Handwheel for emergency operation

- High temperature packing or cryogenic extension

- Stainless steel actuators for corrosive environments

- Stroke limiters, position feedback, valve positioners & limit switches

These valves are ideal for more demanding processes where tight shut-off, temperature resistance, and durability are critical.

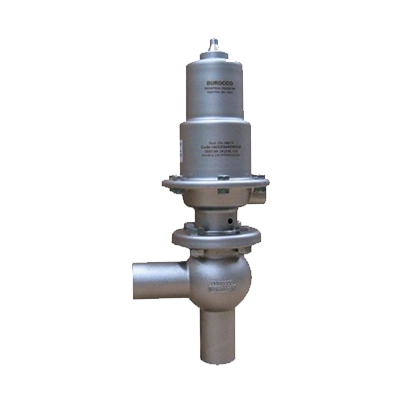

Free Flow Valves – Angle Seat Design

Series VPFL, NPFL & MVPFL (including BW, FL, FF-SW variants)

- DN 8–200, PN16–PN25 rating

- Stainless steel construction for corrosion resistance

- Compact angle-seat design for high flow rates and minimal pressure drop

- Operating temperature up to +350°C (depending on model)

- Available with butt weld, flanged, socket weld, or threaded connections

- Options: Normally open (NO), double effect (DE), handwheel, solenoids, positioners, and feedback systems

These free flow valves are particularly well-suited to chemical plants, water treatment, food & beverage, and general industrial service.

Angle Valves – SBS Series

- DN 15–150, PN16 rating

- Stainless steel body construction

- Pneumatic piston actuation (4–8 bar supply)

- High flow capacity with compact design

- Options for steam service, handwheel, limit switches, and special executions

Micro & Square Valves Series

MVPFL & MVPS

- DN 8–25, PN16–PN25 rating

- Ideal for applications requiring precise, compact shut-off solutions

- Available with visual indicators, solenoid control, and feedback options

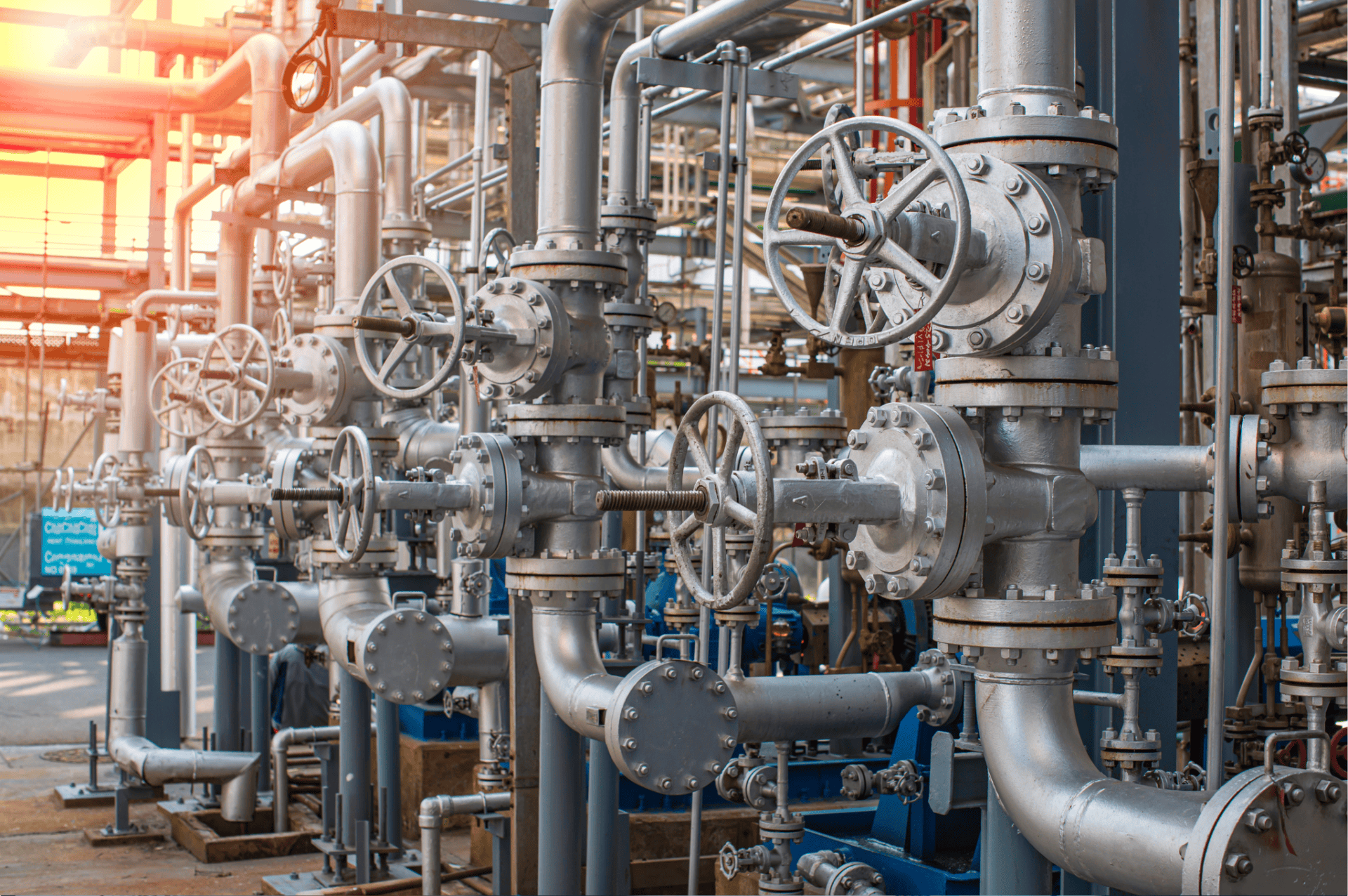

Related industries

Marine

Industrial seals and valves provide safe, reliable and efficient operations in the marine industry, especially in LNG. These components help prevent leaks and maintain proper pressure, ensuring safe transportation and storage of LNG, reducing maintenance costs and improving efficiency.

Oil & Gas

Our products provide the leading solutions both on and offshore within the oil & gas industry. We provide the first choice in terms of safety and reliability.

Energy

The energy sector has a high demand for safe and reliable products. KLINGER is able to provide high-quality advanced solutions for this industry.

District Heating

We are proud to assist in providing durable leak-proof materials for all heating needs across the district.