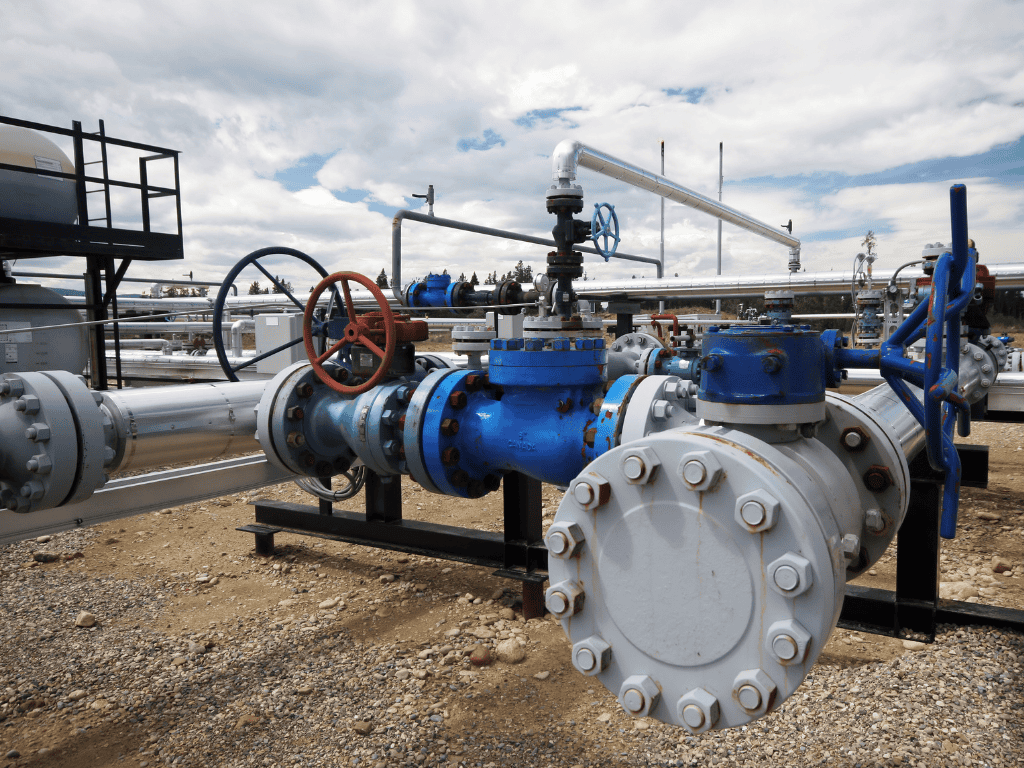

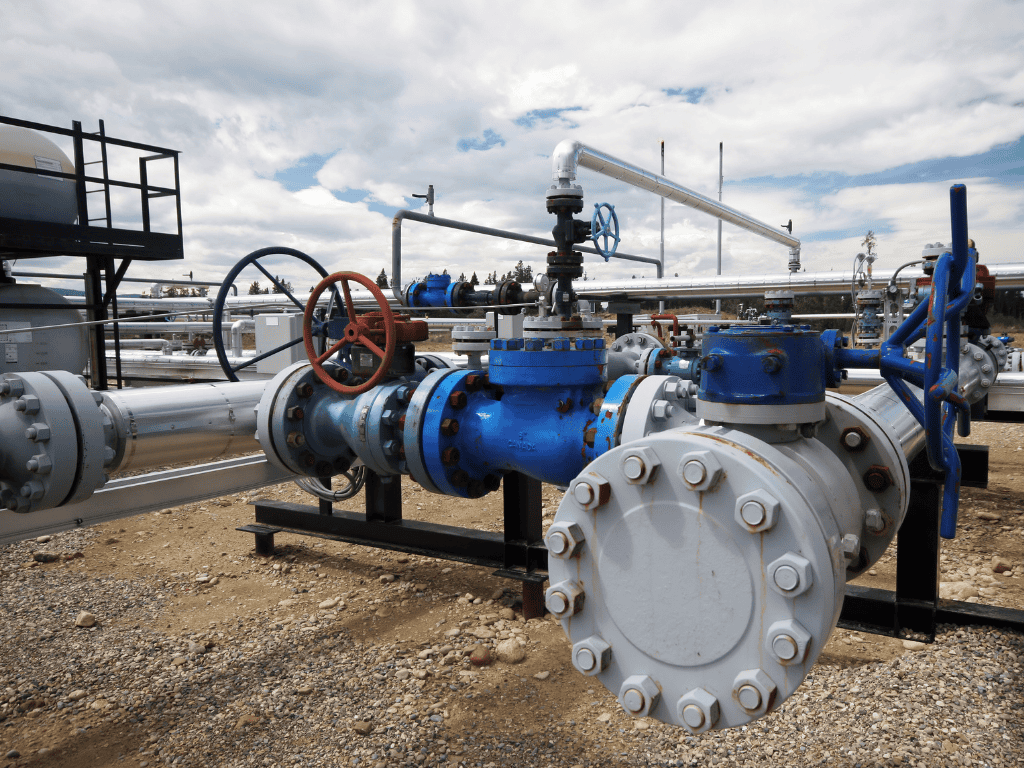

In this blog post, we’ll highlight five common challenges in flange integrity management and provide actionable solutions to help you address them effectively.

1. Lack of Real-Time Monitoring and Data Access

A major challenge in flange integrity management is the lack of real-time monitoring capabilities. Without real-time data, it becomes difficult to spot potential issues before they escalate into costly failures or hazardous situations.

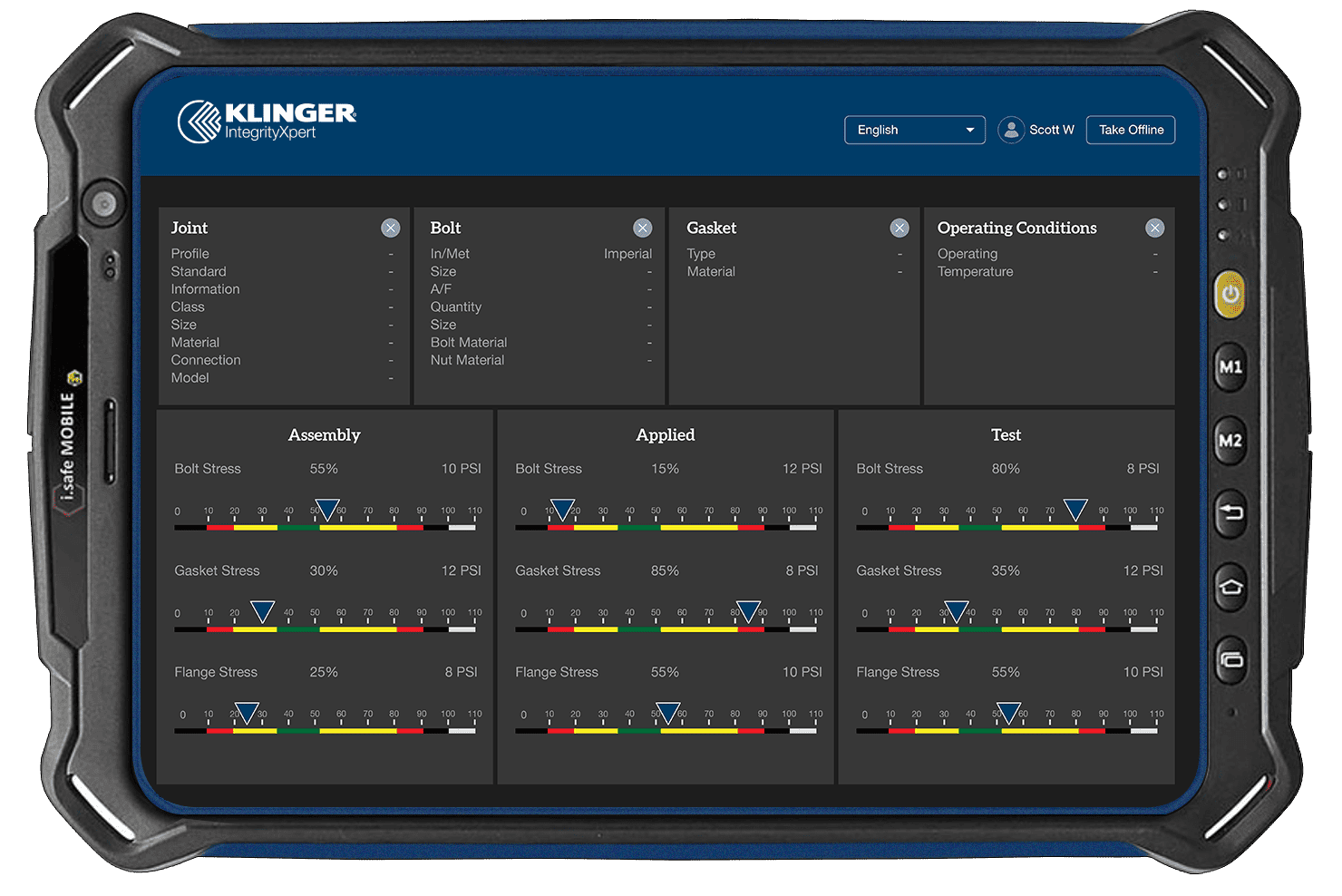

Solution: Implementing Advanced Monitoring with IntegrityXpert

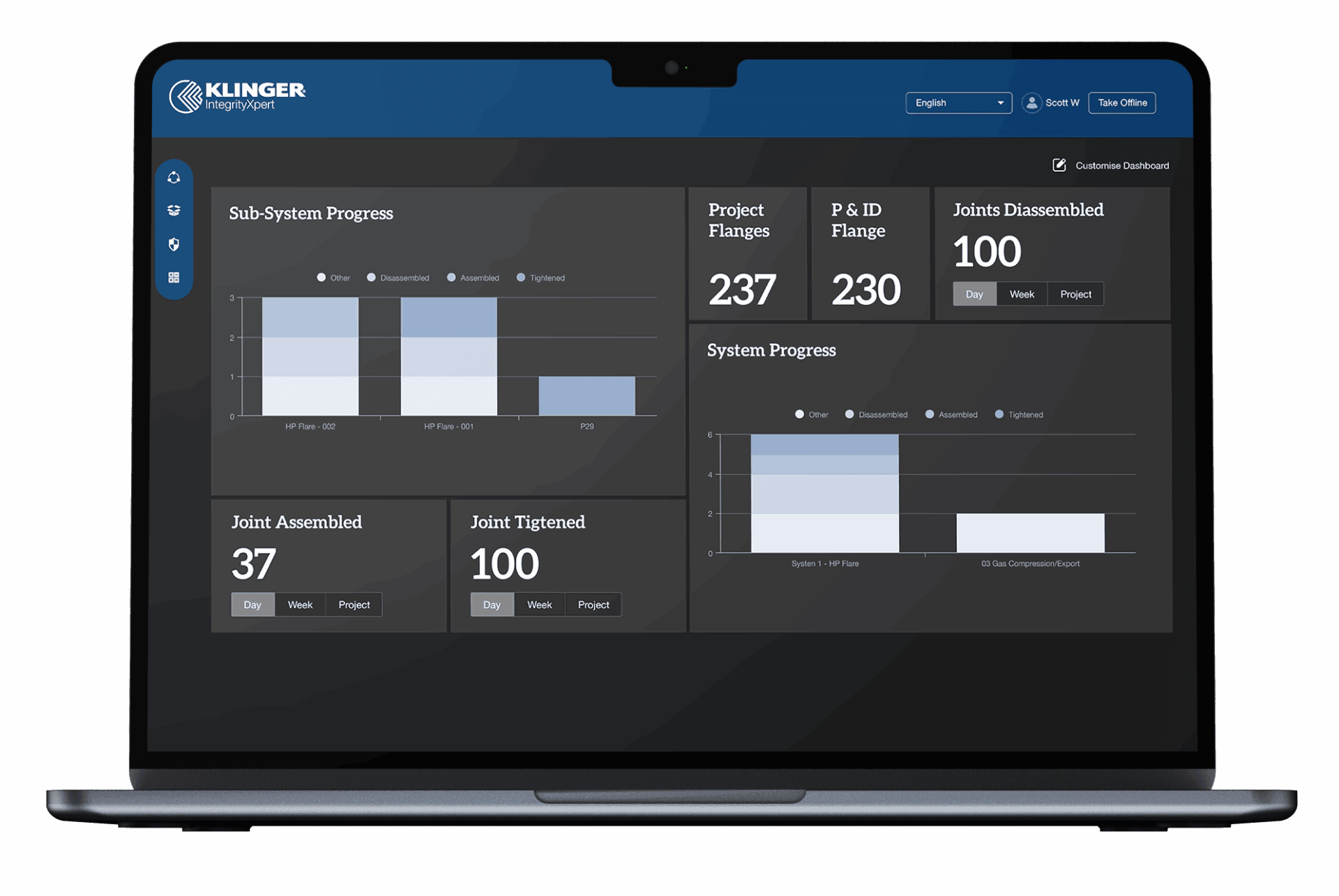

With IntegrityXpert, you can access real-time data on the condition of your flanges, ensuring you have the information you need to make timely and informed decisions. Our software enables ongoing monitoring, recording, and analysis of critical flange performance metrics, so you can detect issues like leakage, corrosion, or wear before they become a problem.

2. Inconsistent Inspection Processes

Inconsistent or infrequent inspections often result in unnoticed flaws or damage that can compromise flange integrity. Without a structured approach, it can be challenging to ensure that inspections are thorough and that all components are consistently assessed.

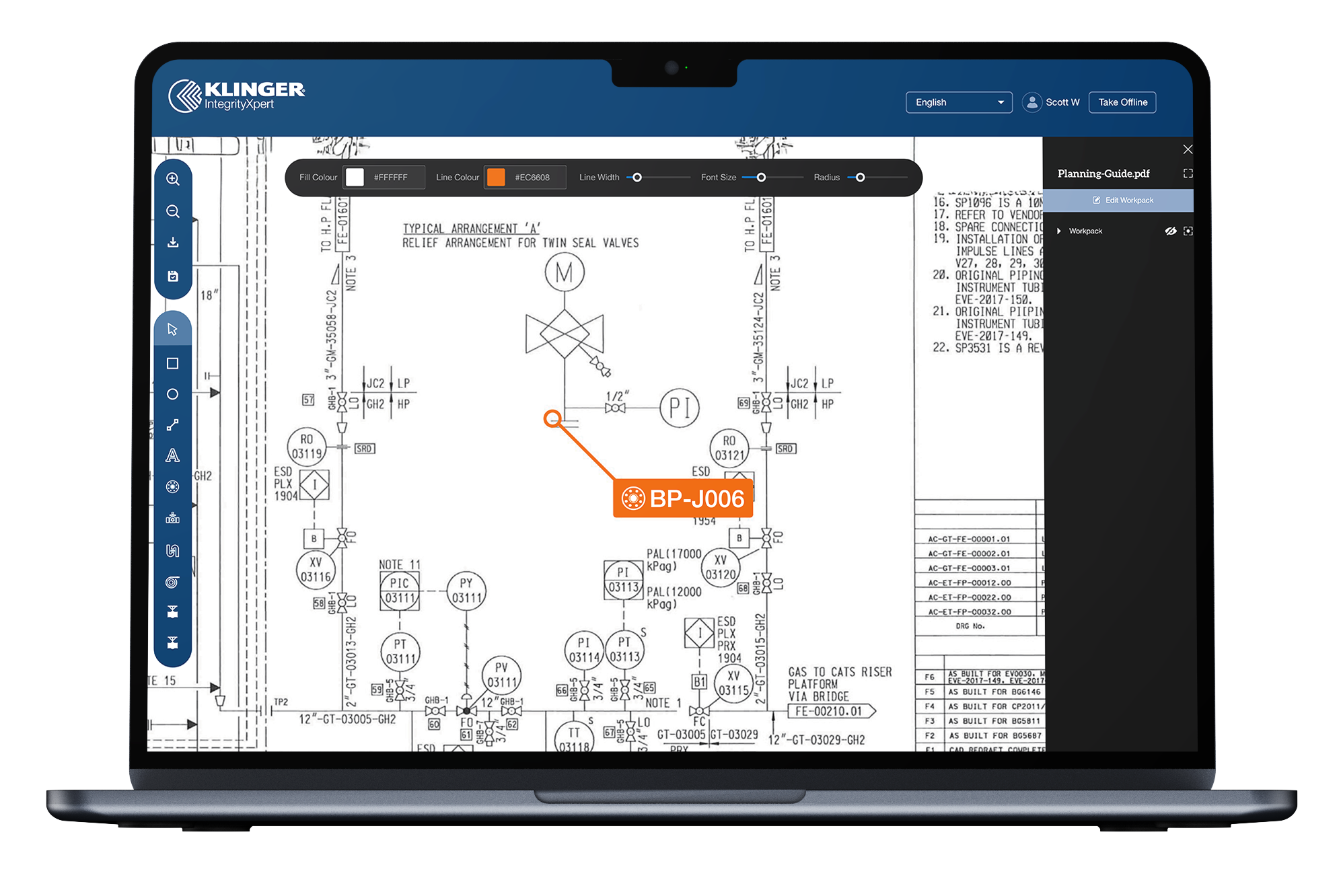

Solution: Standardised Inspection Protocols with IntegrityXpert

IntegrityXpert streamlines the inspection process by providing standardised workflows for all your inspections. With the help of our intuitive interface, you can easily track inspections, set reminders for scheduled maintenance, and ensure all aspects of flange integrity are covered. By automating these processes, you can minimise human error and reduce the likelihood of missed checks.

3. Lack of Comprehensive Historical Data

Flange integrity management relies heavily on historical data to identify long-term trends and predict future issues. Without comprehensive records, it can be difficult to spot recurring problems or assess the effectiveness of past maintenance efforts.

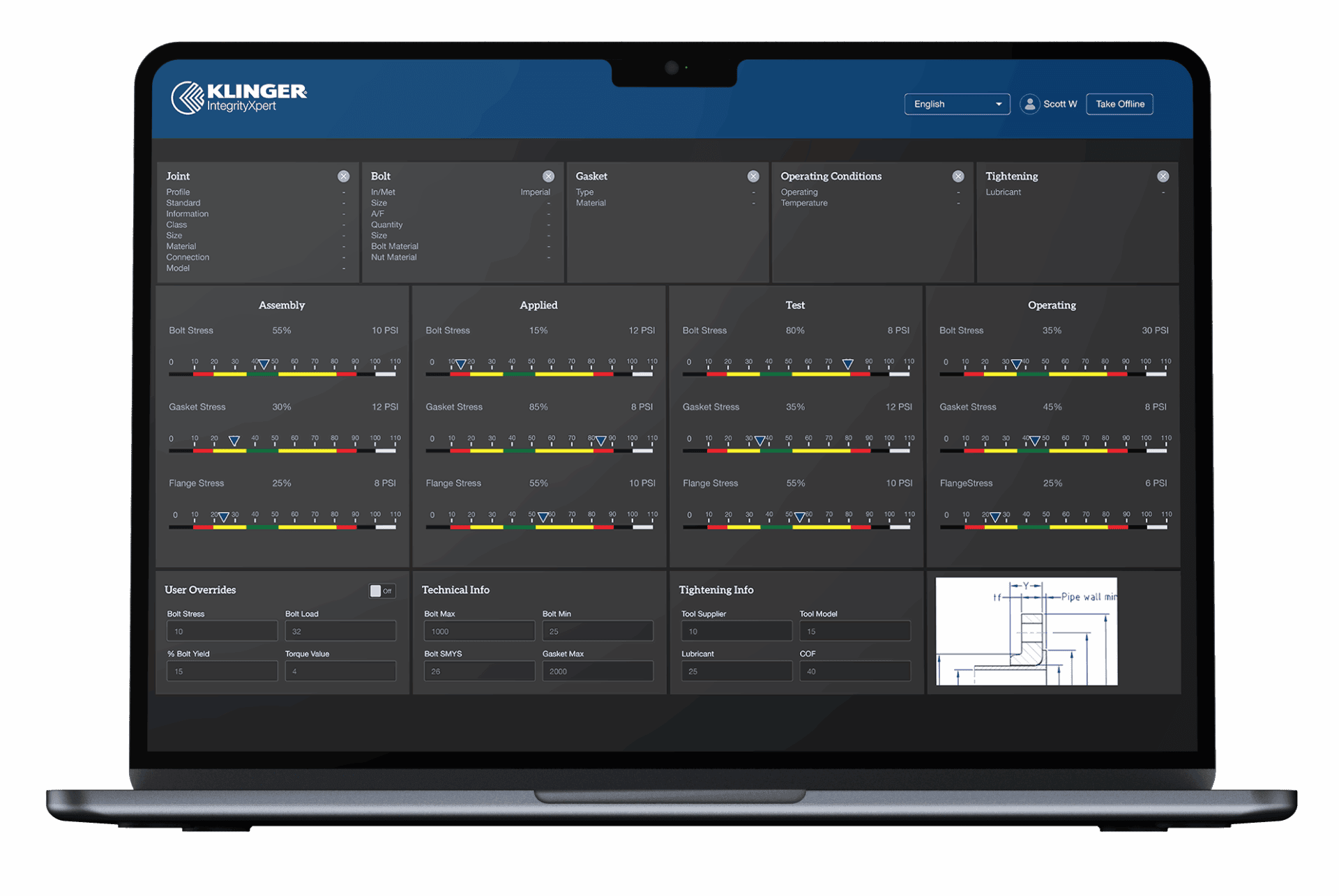

Solution: Centralised Data Storage with IntegrityXpert

Our IntegrityXpert software consolidates all your flange integrity data into one centralised, easily accessible location. You can effortlessly review historical records, track performance over time, and identify trends that can help you predict future maintenance needs. This robust data analysis empowers you to take proactive measures and optimise the lifespan of your flanges.

4. Difficulty in Managing Multiple Sites or Assets

Managing flange integrity across multiple locations or assets can quickly become overwhelming, particularly in large-scale operations. Coordinating inspections, tracking maintenance, and ensuring compliance can result in inefficiencies and increased risk if not managed properly.

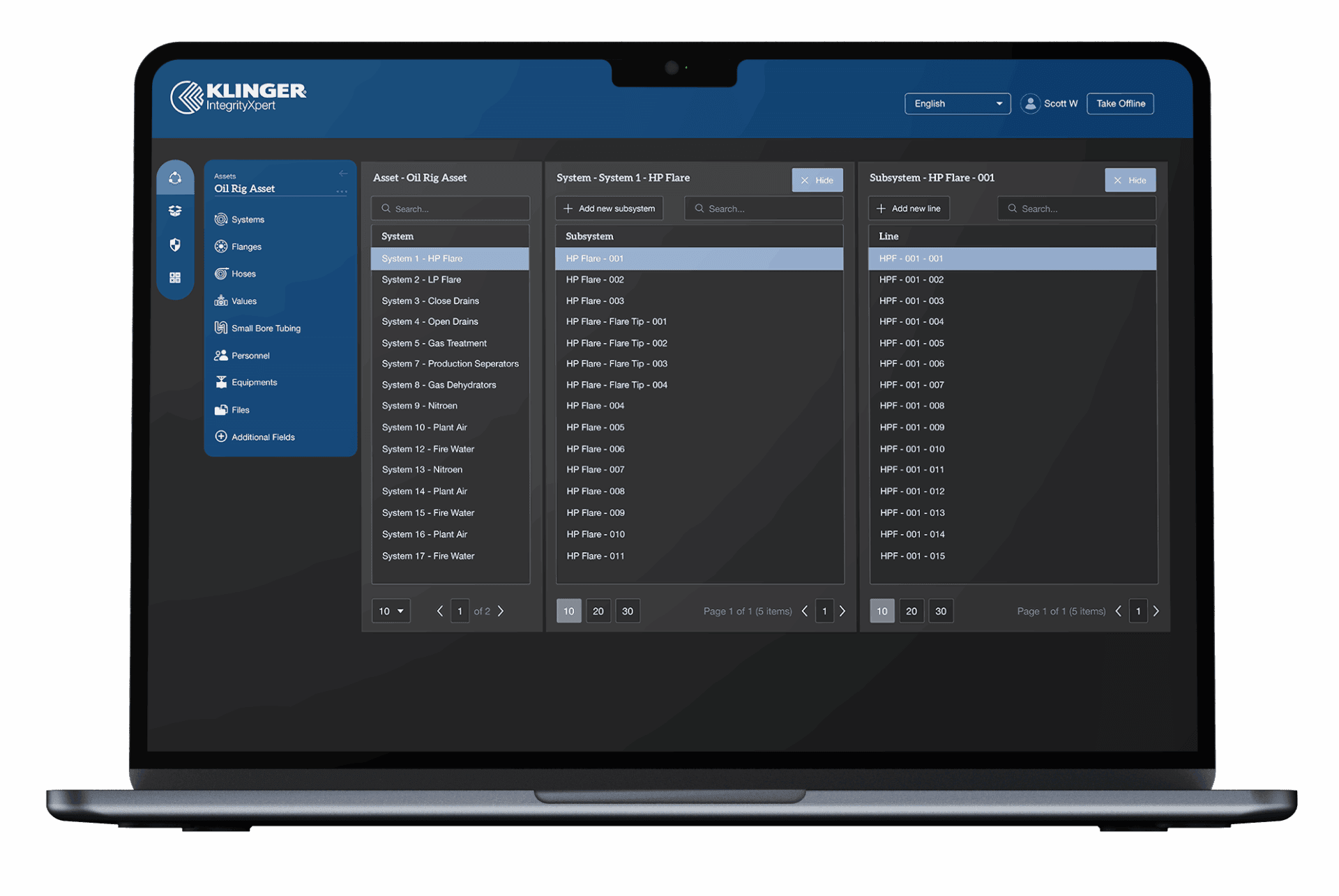

Solution: Multi-Site Management with IntegrityXpert

IntegrityXpert is designed to simplify the management of flange integrity across multiple sites. With its user-friendly platform, you can monitor and manage all of your assets from a single dashboard, ensuring consistency across all locations. Our software allows you to customise and centralise your approach to flange management, helping you streamline operations and reduce complexity.

5. Lack of Training Records

Inconsistent and improper assembly techniques lead to the most flange failures in industry with an estimated 1 in 5 flanges have been assessed to fail PCC-1 requirements. These failures cause Health and Safety incidents as well as an increase in downtime and production costs.

Solution: Competency Matrix

KLINGERs IntegrityXpert Competency Matrix allows sites to track the qualifications of their practical crews and get alerts when it is time for renewal requirements ensuring all personnel are trained to the latest Industry standards. KLINGER can also offer of comprehensive KLINGER Joint Integrity Course which focuses on the key elements to sealing flanges as well as aligning with the current recognised training boards.

Conclusion

Flange integrity management can be challenging, but with the right tools and strategies in place, these challenges can be effectively mitigated. IntegrityXpert offers a comprehensive solution that addresses the key issues in flange integrity management, from real-time monitoring and standardised inspections to centralised data management and regulatory compliance.

By implementing IntegrityXpert, you not only ensure the safety and reliability of your assets, but you also enhance operational efficiency and reduce the risk of unexpected downtime. Book a live demo of the software with one of our experts today.