Liquid Level Gauges

Wherever levels need to be measured and displayed directly.

KLINGER Liquid Level Gauges

The key factors in choosing a gauge are the medium, along with the pressure and temperature range in which it will be used. These determine the design, choice of construction materials, and ultimately the price of the gauge. KLINGER liquid level gauges are suitable for virtually all media encountered in practice, with construction materials ranging from low-temperature steels to high-tensile, heat-resistant steel.

The only exception is high-pressure bi-colour indicators, which were developed specifically for steam applications.

Meet our gauges:

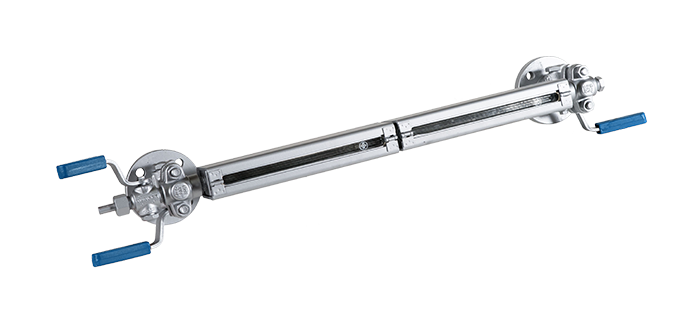

Reflex level gauges

Reflex level gauges allow the medium to be viewed through a reflex glass. The side of the glass exposed to the medium has a prismatic surface, while the other side is smooth. The medium level inside the gauge is indicated by the principle of light refraction: the liquid-filled area absorbs the rays of light completely and appears dark, while the rays of light are fully reflected in the gas/air-filled area, which subsequently appears bright.

Reflex level gauges offer significant advantages in terms of low purchase and maintenance costs, as well as ease of level reading. However, they cannot be used in certain cases—for example, when the separation level between two liquids must be read, when discerning the colour of a liquid is required, or when measuring high-pressure w ater steam.

A105 and SS 316L are used as standard materials; alloy or other materials are available on request.

Product Features:

- Direct view of the fluid level

- More economical solution for fluid level checking

- Different refraction behaviour with liquid and gas

- Easy maintenance and very long service life

- Suitable for steam media up to 32 bar and process media up to 400 bar

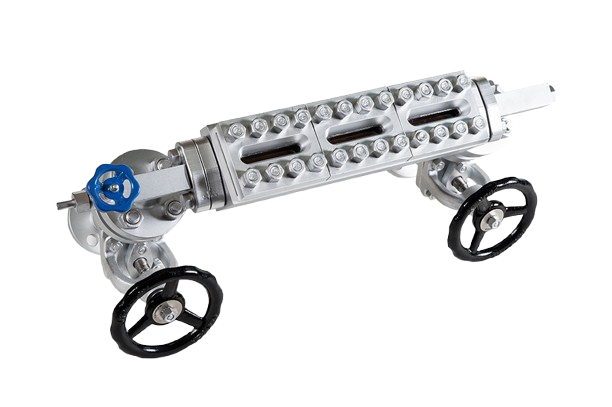

Transparent level gauges

In transparent level gauges the medium is contained within two glasses with smooth surfaces. The level of the medium level can easily be observed by looking through the glass.

Thanks to resistance of the utilized materials, this level gauge is particularly suitable for use with aggressive media or steam. Protective mica shields can optionally be installed between the medium and the glass.

In order to improve visibility under special operating conditions, an illuminator can be mounted on one side of the transparent level gauge.

A105 and SS 316L are utilized as standard materials – alloy or other materials are available on demand.

Product Features:

- Direct view of the fluid level

- Direct vision through the glass (back illumination available)

- Easy maintenance and very long service life

- Suitable for steam media up to 120 bar and process media up to 250 bar

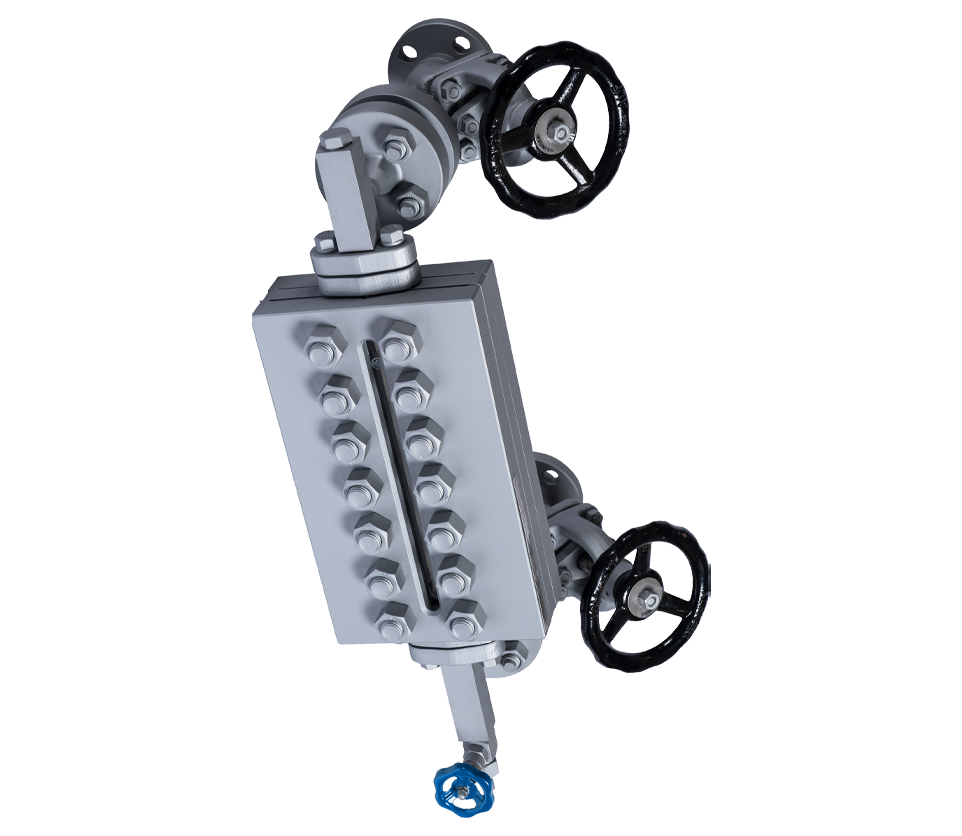

Bi-colour level gauges

Bi-colour level gauges are primarily used to measure high-pressure water steam. These gauges feature two flat transparent glasses mounted at an angle to each other. Together with the gauge body, they form the chamber containing the medium.

A special red and green illuminator, creating a dual lighting system, is mounted on the rear side of the gauge body. In this system, red indicates steam and green indicates liquid.

A105 is used as the standard material.

Product Features:

- Leakage rate A to EN 12266-1 — tight both in the bore and to atmosphere

- Fire-safe, automatable designs

- Resistant to erosion and temperature shock

- Easy to service without removing from the pipeline

- Available with special designs: oxygen-cleaned, control end position, regulation versions, ISO actuator flange, heating jacket

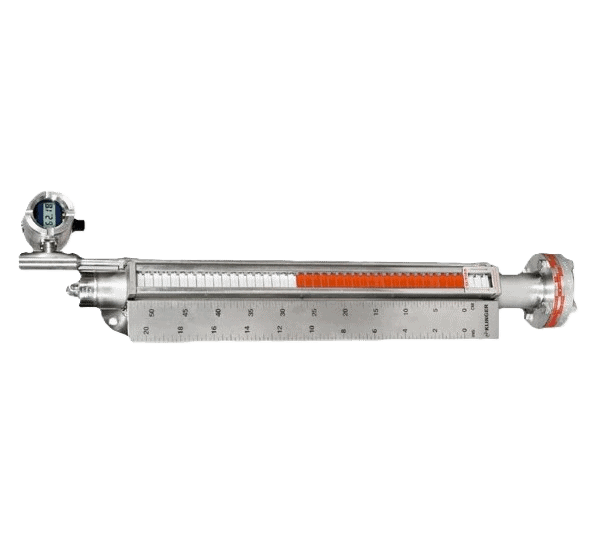

Magnetic Level Gauges

KLINGER offers a dedicated range of magnetic level gauges, engineered for accurate and reliable liquid level measurement in industrial applications.

The gauges operate on a straightforward principle: the process fluid enters the measuring chamber, which is directly connected to the vessel. This ensures the liquid level in the chamber exactly matches the level in the vessel, providing consistent and precise indication of process conditions.

Our magnetic level gauges deliver a reliable and accurate solution for monitoring liquid levels, even in demanding environments. Featuring clear, highly visible indicators, they provide real-time, easy-to-read level monitoring without the need for external power sources.

Designed for durability, KLINGER magnetic level gauges maintain performance in high-pressure, high-temperature, and corrosive conditions, offering long-term reliability in critical applications.

Read more

Borosilicate Gauge Glasses

The Quality of a sight (gauge) glass depends mainly on the chemical composition and mechanical strength of the glass material. Analyses and acid/alkali tests constantly ensure a high glass-quality. The mechanical strength is reached by thermal prestressing. KLINGER gauge glasses are suitable for installation in liquid level gauges of almost any type.