Over the years, we have developed a quick and meticulous manufacturing process, accompanied by our strategically positioned network of service centres, to bring that fast turnaround time to life.

Why Turnaround Time Matters in Industrial Sealing

A fast turnaround time is vital when it comes to industrial sealing. Not only can downtime cause significantly negative concerns to the financial aspects of a plant, but it can also pose substantial safety risks. Choosing to partner with KLINGER UK can reduce downtime, eliminate leak risks, and enhance overall safety across your operations.

How KLINGER UK Delivers a Fast Turnaround

Here at KLINGER UK, we are ahead of the game when it comes to manufacturing. Our dedicated team who manages our manufacturing capabilities are always investing their time into how we can adapt and develop our systems to retain our profound qualities whilst increasing our speed of manufacturing.

Twinned with this, we have 7 areas around the UK, in Bradford, Southampton, Runcorn, Immingham, Middlesbrough, Grangemouth, and Aberdeen that provide a supply of readily available products. These strategically positioned Service Centres allow us to fulfil the needs of the most demanding of applications nationwide. We also have manufacturing capabilities at selected locations, where sealing solutions are most required.

A Broad Product Range, Delivered Fast

To meet our clients needs, we have list of high demand products that have been tried and tested in different scenarios. Our range delivers complex solutions to sealing concerns.

Meet the Range of KLINGER Products:

- Metallics & Semi-Metallics

- Jointing Materials

- Valves

- Insulation Sets

- Compression Packings

- Associated Products

At our headquarters in Bradford, we also have a dedicated unit that delivers Precision Engineering, enabling advanced custom manufacturing capabilities.

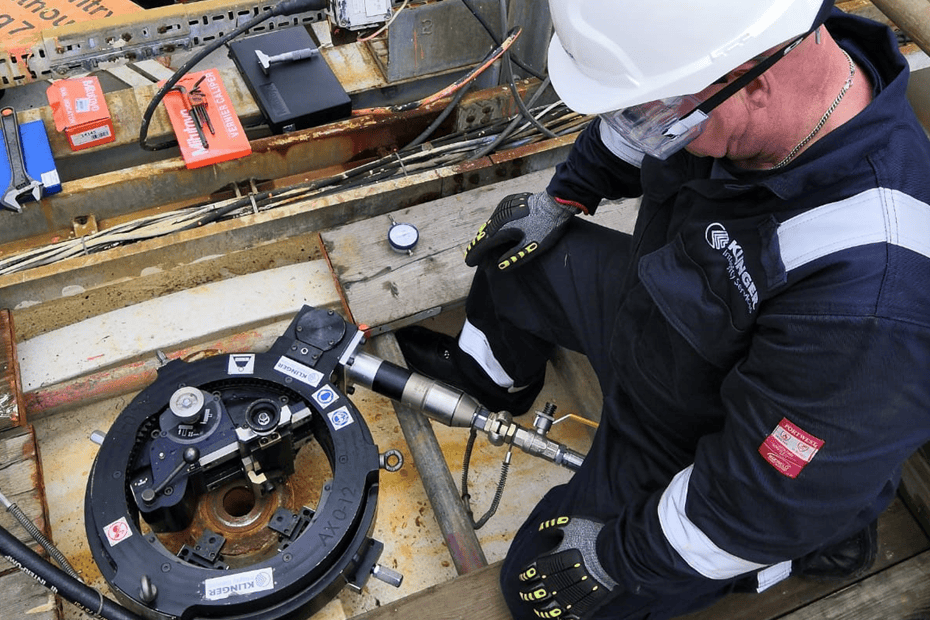

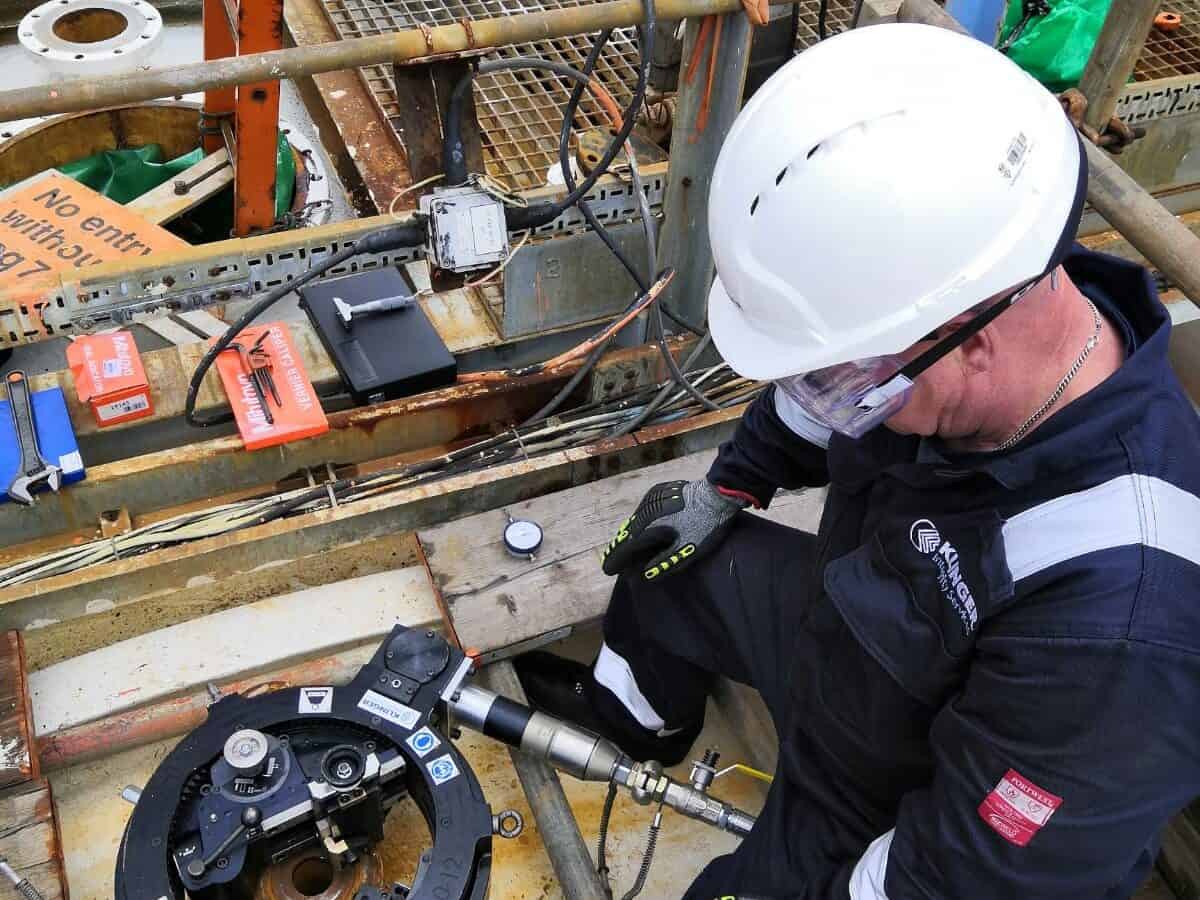

24-Hour Assistance with KLINGER Integrity Services

Need urgent on-site support? KLINGER UK is proud to offer a rapid 24-hour response service, with skilled technicians available across the country. Whether it’s a planned shutdown or an unexpected issue, our team is ready to be on-site fast — helping you minimise downtime and keep operations running safely and efficiently.

Our technicians are handpicked for their expertise, industry knowledge, and commitment to quality. Each specialist excels in their field, ensuring the service you receive is second to none.

Here’s what we offer:

- Flange Management – Ensuring your flanged joints are correctly assembled, tracked, and maintained for long-term integrity

- Controlled Bolting – Accurate application of bolt load using calibrated tools and procedures

- Bolt Torquing & Tensioning – Minimising the risk of leaks through precision tightening techniques

- Leak Testing & QA/QC – Verifying joint integrity and system safety through advanced testing methods

- On-Site Precision Machining – High-accuracy machining services brought directly to your site

- Hot Bolting – Safely replacing or tightening bolts on live systems without the need for shutdown

- Hydraulic Testing Services – Pressure testing systems and components for compliance and performance

- IntegrityXpert Flange Management Software – Digital flange tracking that enhances traceability, safety, and compliance – Discover how this service can help you!

Turnaround Time That Builds Trust

With our combined products and services, we can provide solutions to suit your requirements. Over the years we have developed a portfolio of real-life case studies of various industries using a collection of different products and applications. KLINGER is a ‘trusted. worldwide.’ company, that retains its name over a history of over 130 years.

Here’s what our clients have to say:

“I find KLINGER onshore support very professional through the yard trials and during the execution phase, the two KLINGER technicians carrying out the work offshore also showed the same professionalism throughout the work scope. I would recommend the use of KLINGER Services and the Hot Bolt Clamping System in the future where Hot Bolting Flanges is required”

Get in touch today to request case studies that reflect your applications.